Hydrogen Refueling Equipment

he multi-purpose hydrogen refueling equipment is used for refueling hydrogen fuel cell drones and other hydrogen energy systems. This equipment has high safety, reliability, efficiency, and convenience, and can be adapted to various uses and requirements

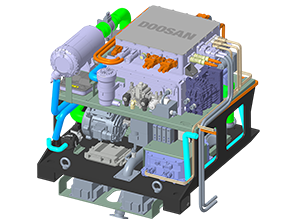

Hydrogen Refueling Equipment-BHR-350

· Controller, compressor, cooler and dispenser(charging part) are all-in-one for easy maintenance and easy installation

· Easy and intuitive GUI application allows general users without hydraulic and pneumatic knowledge to use

· Internal Cooling system is applied to charge even in high temperature environments

Control board & LCD Monitor

Cooling System

Booster/Compressor

Laser Measuring Device and Hydrogen Container

Charging gun for fixed charging container

Control board & LCD Monitor

Cooling System

Booster/Compressor

Laser Measuring Device and Hydrogen Container

Charging gun for fixed charging container

TECHNICAL DESCRIPTION

Pressure explosion proof structure has been applied (always maintained at least 50pa) to prevent gas from inflowing into the control box even if hydrogen gas leaks.

The high-pressure part is applied with a steel plate greater than 6mm to protect the user in the event of an accident.

When charging hydrogen, it detects and controls changes in volume and temperature of containers in real time using infrared laser.

Pressure explosion proof structure has been applied (always maintained at least 50pa) to prevent gas from inflowing into the control box even if hydrogen gas leaks.

The high-pressure part is applied with a steel plate greater than 6mm to protect the user in the event of an accident.

When charging hydrogen, it detects and controls changes in volume and temperature of containers in real time using infrared laser.

- Controller, compressor, cooler, dispenser, etc. are all-in-one systems.

- Specially designed for loading on trucks and vehicle trailers.

- It can be installed and used not only as a mobile but also as an on-site fixation wherever it is indoors & outdoors.

- Compact size and lightweight for manual and automatic operation. (default automatic)

- It can be used in environments with high external temperatures and increases safety when charging by applying the internal cooling system.

- It is equipped with a dedicated SW with the optimal algorithm for charging TYPE3 and TYPE4 hydrogen containers, and fully automatic charging operation is possible through various sensor information.

- BOP and control algorithms considering the characteristics of hydrogen containers (TYPE3, TYPE4) for mobility have been applied.

- Various sensors have been applied to predict and measure various situations such as pressure rise due to temperature rise, explosion, fire, etc., and prevent accidents when charging. We have secured stability by lowering the possibility of accidents.

- IEC and KOSHA explosion proof standards were applied to each area of hydrogen charging equipment to separate zones, and appropriate explosion proof grades and certified products were applied to each zone.

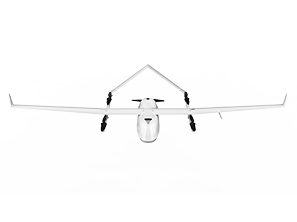

APPLICATION

Using a hydrogen fuel cell stack, it is used as a charging device for various hydrogen

Hydrogen Refueling Equipment Specs

Product |

Hydrogen Refueling Equipment |

Hydrogen Charging Pressure |

0bar ~ 400bar |

|---|---|---|---|

Size |

80cm x 168cm x 195cm(H) |

Charging Method |

Air Driven (electrically driven selectable) |

Monitor |

13inch multi-touch monitor |

Supply Gas |

AIR (Over5bar), N2 (under 1bar) |

Material |

SUS302, SCP |

Charging Speed |

Over50Nlpm(at a room temperature) |

Thickness |

6T(Explosion zone), 1.5T(General zone) |

Power |

110Vac or 220Vac |

Post processing |

Powder painting |

Cooling system |

Double-tube type water cooling system |

Weight |

under 600kg |

Etc. |

Electrically driven selection eliminates the need for nitrogen supply. Nitrogen needs a small amount for flushing |

Safety Specifications |

Sensor : PSV, TPRD, Displacement Detection, Gas Detection, Fire Detection, Pressure, Temperature |

Interface |

Apply touch-monitoring GUI Provides remote monitoring and emergency control PC version software. |

Explosion Proof Certification |

Kosha Kcs, IEC EX certification, etc. (scheduled) |